Launch of finishing line for digital label printing

Launch of finishing line for digital label printing

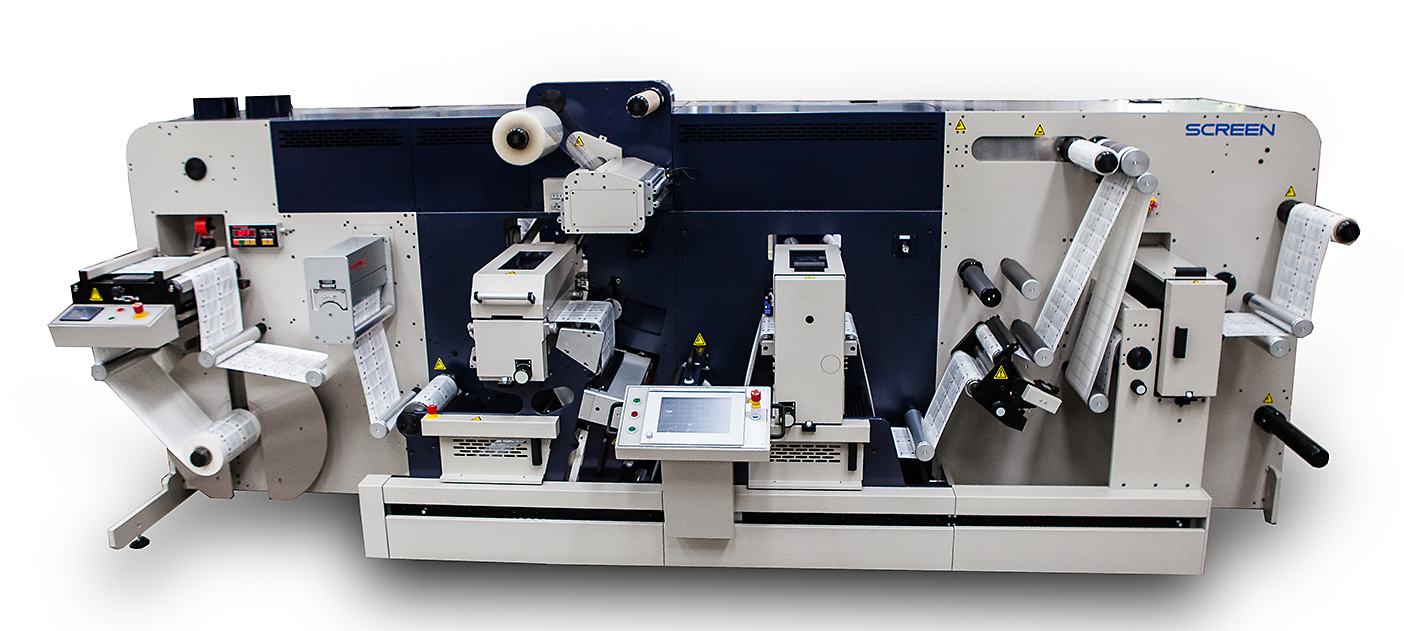

Dainippon Screen's Media And Precision Technology Company is scheduled to begin sales of its new JetConverter L350 digital label finishing line in October. This system can be used with Screen's existing Truepress Jet L350UV inkjet label printing system to enable the construction of a fully integrated production line, spanning from data input to printing and processing and finishing.

The JetConverter L350 will be on display and also performing demonstration runs at Labelexpo Americas 2014, to be held in Rosemont, Illinois, United States, from September 9 (Tuesday) to 11 (Thursday).

Outline

With the increasing diversification of product packaging, the label printing industry has been experiencing a marked rise in orders for small-lot and quick-turnaround jobs. To meet these needs, Screen launched the Truepress Jet L350UV digital label printing system in September 2013. This powerful system is able to deliver world-leading throughput of up to 50 meters (164 feet) per minute.

The JetConverter L350 digital label finishing line offers similar high-speed processing of 64 meters (209.9 feet) per minute, enabling it to be used with the Truepress Jet L350UV. Throughput may vary depending on such factors as the type of media and feed volume (repeat length) used.

Together, these systems allow the construction of an integrated production line that runs from data input right through to label finishing.

The JetConverter L350 is also equipped with many new standard functions for label printing, including varnishing, lamination, die-cutting and slitting, providing high-speed processing. In addition, advantages such as decreased times for setup and adjustment and reduced paper wastage achieved by a shorter path line enable significant cost reductions during label production.

It will soon be possible to perform automatic setup by linking the JetConverter L350 with a management information system and also to connect it inline to the Truepress Jet L350UV. This will provide full automation enabling one-pass processing from data input through to label finishing.

Screen plans to continue with this expansion of its product lineup, steadily adding prepress and postpress systems that are designed specifically for digital printing presses.

Features

A full range of key functions for postpress of labels incorporated into a single compact system, including flexo coating (full and spot varnishing), lamination/cold foiling, die-cutting, back scoring, waste matrix stripping and slitting

High-speed processing of up to 64 meters (209.9 feet) per minute

Simplified operation enabled by features including a sliding, touch screen controller

Major reduction in waste paper achieved by creating the shortest possible path line

Screen USA will demonstrate the JetConverter L350 running live jobs at Labelexpo Americas 2014 in Booth #3005 from September 9-11 at the Donald E. Stephens Convention Center in Rosemont, Ill.

www.screenusa.com