The findings of the semi-industrial trial come out of a study initiated by Avery Dennison and performed by The National Test center Circular Plastics assessing the releasability of filmic labels during rigid HDPE packaging recycling

The findings of the semi-industrial trial come out of a study initiated by Avery Dennison and performed by The National Test center Circular Plastics assessing the releasability of filmic labels during rigid HDPE packaging recycling

Avery Dennison, a global leader in materials science and digital identification solutions, recently conducted a semi-industrial trial to assess label releasability and the quality of recycled packaging flakes during the rigid HDPE recycling process, in cooperation with The National Test center Circular Plastics (NTCP).

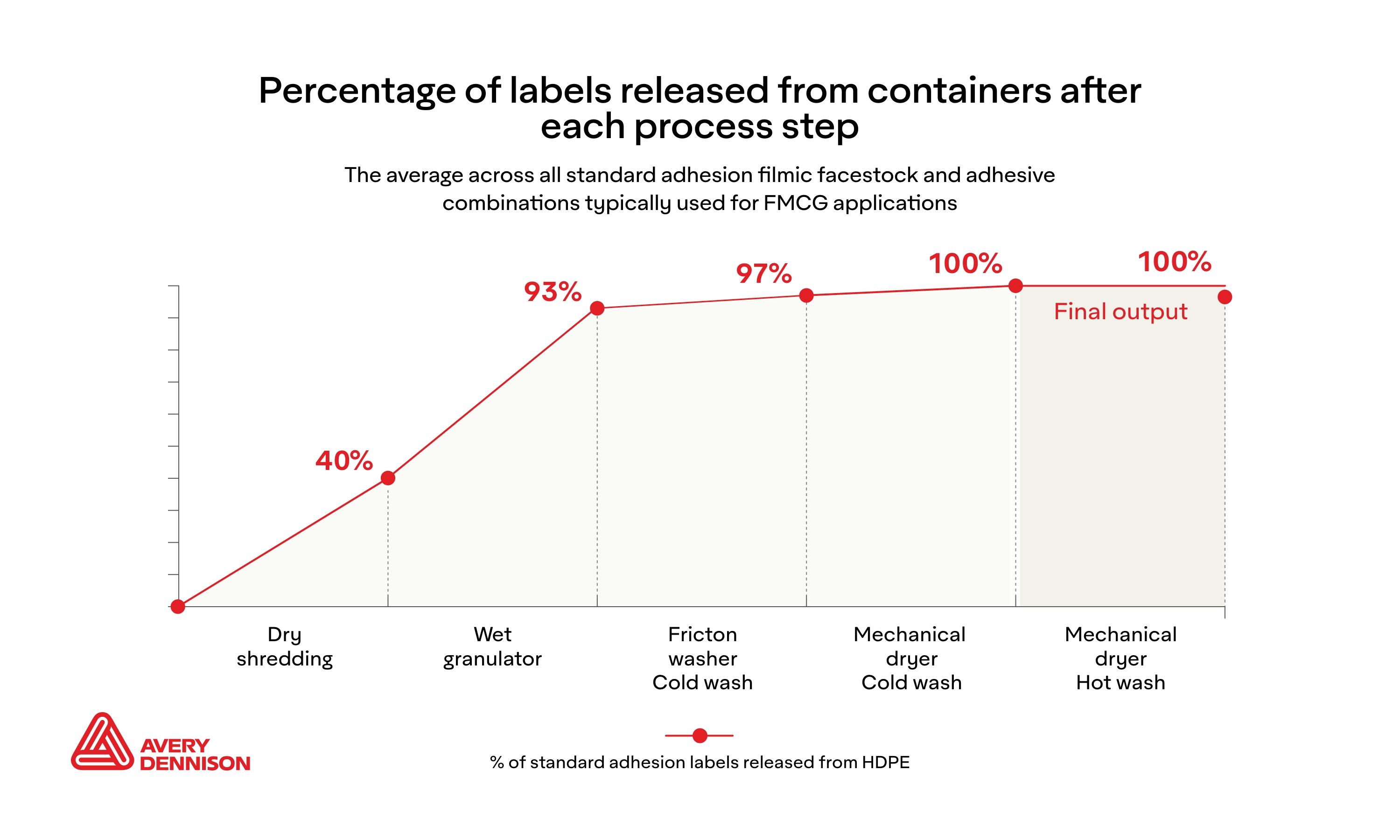

The scientific results demonstrate that Avery Dennison’s standard adhesion filmic label solutions for FMCG applications are fully released from the HDPE packaging during the recycling process even under cold wash conditions.

During the trial, 50,000 white HDPE bottles with different combinations of filmic face materials and emulsion adhesives were tested. It was found that 1) 100% of Avery Dennison's standard adhesion filmic label solutions are released from HDPE packaging during the recycling process, resulting in clean HDPE flakes and 2) mechanical stress is a critical factor in enabling label releasability and must be included in testing protocols.

The results show that current requirements for label adhesives to wash off in either hot or cold temperatures will have little impact on label releasability during recycling. This indicates there is potential for recycling associations and regulatory bodies to update existing design for recycling guidelines for HDPE decoration. The results also show that FMCG brands do not need to seek out separate labeling solutions that enable recyclability, since Avery Dennison’s standard adhesion filmic label solutions are compatible.

“These results challenge the widely held belief that self-adhesive labels do not separate from HDPE packaging during the cold temperature washing step in the recycling process,” says Alena Maran, Director of Strategy and Sustainability at Avery Dennison, EMENA. “Until now, we did not have fact-based evidence that showed how our labels react during the multiple steps in the recycling process. We can now clearly see that the requirements in existing design for recycling guidelines and test protocols for wash-off labels are not necessarily representative of the full-scale HDPE recycling process.”

“Using our semi-industrial recycling line, we work to find ways to improve the sorting and washing of plastics during the recycling process,” adds Freek van Rhijn, Technical Director at NTCP. “We welcome the research questions and cooperation with Avery Dennison on this scientific trial, one of the largest and most extensive label releasability trial on an industrial scale ever performed in Europe so far.”

To learn more about the results of the semi-industrial trial and the role of the label in design for recycling, join the live event hosted by Avery Dennison and Packaging Europe on March 6th.

Note: The semi-industrial trial conducted did not asses the recycling steps that occurred after washing (e.g. extrusion). The claims presented by this trial are under the condition that the label has passed sorting requirements.

www.averydennison.com